Itekhnoloji yokumakisha yomatshini wokumakisha we-laser isetyenziswa ngakumbi nangakumbi kwintsimi yokushicilela, kwaye umatshini wokumakisha we-laser usetyenziswa kwiiplastiki, isinyithi, iitshiphusi zePCB, iitshiphusi zesilicon, ukupakishwa kunye nezinye izinto., Ukukrolwa komatshini, ukuprintwa kwesikrini, ukubola kweekhemikhali kunye nezinye iindlela, ngexabiso eliphantsi, umthamo ophezulu, kwaye unokulawulwa yinkqubo yekhompyutha, ukwenza imizobo kunye nokumakisha imizobo kunye nokubhaliweyo okufunayo, kunye namandla okumakishwa okuveliswa yi-laser. esebenza kumphezulu we-workpiece isigxina Ukwabelana ngesondo luphawu olubalaseleyo.

Okwangoku, kwishishini lokumakisha kunye nokushicilela, oomatshini bokuphawula nge-laser bathathe ngaphezu kwe-90% yemarike.Isizathu sokuba oomatshini bokumakishwa kwelaser banesabelo esikhulu kangaka kungenxa yokuba banezi nzuzo zisi-8 zilandelayo:

1. Ngokusisigxina:

Amanqaku omatshini wokumakisha i-Laser akayi kuphelelwa ngenxa yezinto ezisingqongileyo (umnxeba, i-asidi kunye nokunciphisa igesi, ukushisa okuphezulu, ukushisa okuphantsi, njl.).

2. Ukuchasana nenkohliso:

Uphawu olukrolwe ngeteknoloji yomatshini wokumakisha ngelaser akulula ukuluxelisa kunye nokutshintsha, kwaye lunamandla okuchasa umgunyathi.

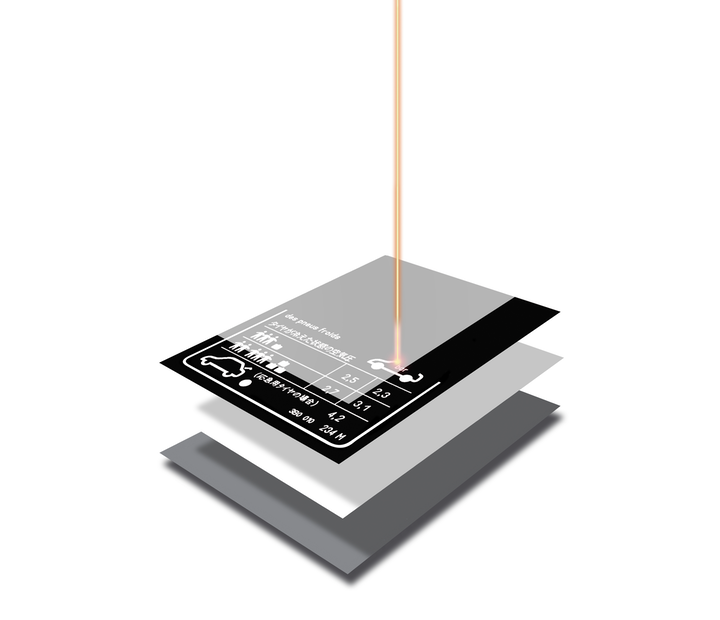

3. Ongaqhagamshelwanga:

Ukumakishwa kwe-Laser kucutshungulwa ngumatshini ongeyena "ummese okhanyayo", onokuprinta amanqaku kuyo nayiphi na indawo eqhelekileyo okanye engaqhelekanga, kwaye i-workpiece ayiyi kuvelisa uxinzelelo lwangaphakathi emva kokumakisha, ukuqinisekisa ukuchaneka komthamo we-workpiece.Akukho mhlwa, akukho konakala, akukho tyhefu, akukho ngcoliseko kumphezulu osebenzayo.

4. Ukusetyenziswa ngokubanzi:

Umatshini wokumakisha i-Laser unokucubungula izinto ezahlukeneyo zetsimbi kunye nezingezizo ezentsimbi (i-aluminiyam, ubhedu, intsimbi, iimveliso zokhuni, njl. njl.).

Izinto zePlastiki

Metal Material

Izinto zeglasi

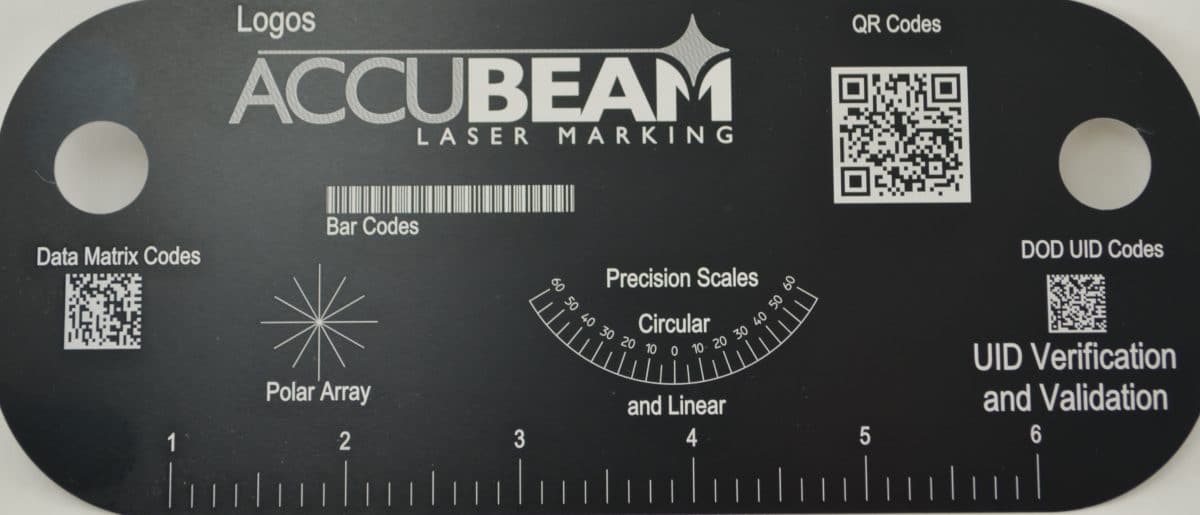

5. Ukuchaneka okuphezulu kokukrola:

Amanqaku abhalwe ngomatshini wokumakisha we-laser aneepateni ezintle, kwaye ububanzi bomgca obuncinane bunokufikelela kwi-0.04mm.Ukumakishwa kucacile, ixesha elide kwaye lihle.Ukumakishwa kweLaser kunokuhlangabezana neemfuno zoshicilelo oluninzi lwedatha kwiindawo zeplastiki ezincinci kakhulu.

6. Iindleko zokusebenza eziphantsi:

Umatshini wokumakisha we-laser unesantya sokumakisha ngokukhawuleza kwaye ukumakisha kwenziwa ngexesha elinye, kunye nokusetyenziswa kwamandla aphantsi kunye neendleko zokusebenza eziphantsi.

7. Ukusebenza okuphezulu kokusebenza:

Ukusebenza okuphezulu kokusebenza kunye nesantya sokumakisha ngokukhawuleza.I-laser beam phantsi kolawulo lwekhompyutheni inokuhamba ngesantya esiphezulu (isantya ukuya kwi-5 ukuya kwi-7 yeemitha ngomzuzwana), kwaye inkqubo yokumakisha ingagqitywa kwimizuzwana embalwa.

8. Isantya sophuhliso olukhawulezayo:

Ngenxa yokudityaniswa kobugcisa belaser kunye nobuchwepheshe bekhompyuter, abasebenzisi banokuqonda imveliso yoshicilelo lwelaser logama nje beqhuba inkqubo kwikhompyuter, kwaye banokutshintsha uyilo loshicilelo nangaliphi na ixesha, oluthatha indawo yenkqubo yokubumba yemveli, kwaye ibonelela ngokunciphisa umjikelo wokuphucula imveliso kunye nemveliso eguquguqukayo.Isixhobo esifanelekileyo.

Ixesha lokuposa: Apr-20-2021